CAPABILITIES

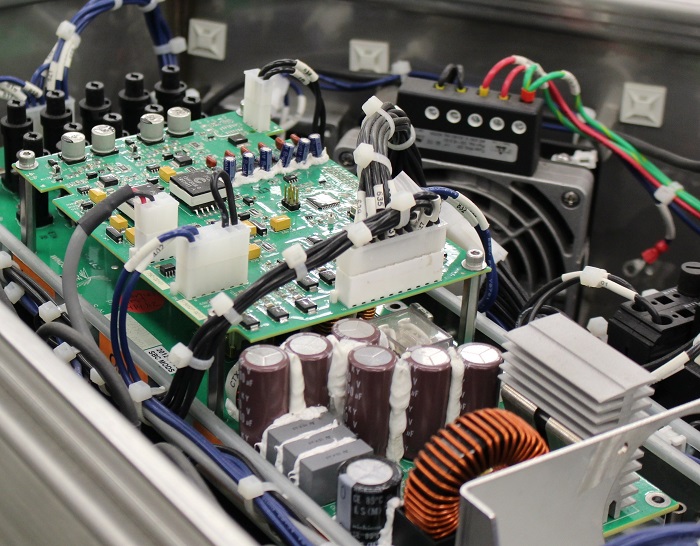

We recognize that client relationships and adaptability are just as crucial as strong engineering skills from design to mass production. We will support your project in the same way as our facilities because we place continual improvement and excellence at the center of our processes. We provide high-end engineering and manufacturing services to all industries as a contract manufacturer. For years, we have been an electronics manufacturing firm and a print circuit board manufacturer, providing PCB design, prototyping, PCB assembly and manufacturing solutions to all of our clients based on their specifications.

FLASHLINE EMS PRIVATE LIMITED CAPABILITIES

- Complete automated SMT line Fuji Aimex II S-2 nos with in-line Zenith Alpha HS+, KOH YOUNG 3D Automated Optical Inspection System.

- Placement Minimum size of PCB of 48 mm x 48 mm and maximum PCB Sizes of 774 mm (L) x 686 mm ( W).

- Lead & Lead free manufacturing facilities to cater local & Export Customer needs.

- Capable of handling smallest component 0402 (01005”) to 74 x 74 and height Up to 25.4 mm.

- Feeder loading capacity of 222 nos of 8 mm feeders and 10 different tray components.

- Option to use loose ICs through vibratory stick feeder,

- Can support assembly for PCBs upto under 0.3 mm thickness.

- Placing accuracy of 50 Microns with chips and 30 Microns in ICs.

- Minimum ball size of 0.15 mm dia and maximum BGA size upto 75 mm x75 mm

- Equipped with 3D Zenith Alpha HS+, KOH YOUNG 3D Automated Optical Inspection System With 5way 3D Projection Light Source to measure height of components upto 25 mm.

- Being supported BGA x –ray inspection thru sub-contracting from the near by EMS companies.

- Single side , double sided PCB assemblies with SMD and leaded components ,testing and system Integration / Box-build assemblies.

- Reflow oven with N2 option to reduce the oxidation of the welding surface and improve the wettability of the welding.

- PCB Assemblies with in-house conformal coating.

- Rework of BGA ‘s and re-balling facility.

- Functional Testing, Burn-in and Environmental tests as per Customer needs.

- Provide support on PCBA prototype , New product introduction and Sample production.

- Flexa Software for line optimization

- ERP to provide clear visibility of the product status.

- Certifications under process : ISO9001:2015 international quality system & AS9100D:2016

Capabilities for fully integrated electronics manufacturing

Flashline is one of the fully integrated electronic manufacturing services providers. We serve our customers at every stage of their product lifecycle through innovative electronic manufacturing services (EMS) capabilities and great customer service, from in-house design to prototype, new product introduction, and mass production.

Advanced features that will help you manufacture your goods more efficiently:

We offer value-added services as a contract manufacturer, shortening time to market while boosting the competitiveness of your projects. We place excellence at the center of our organization. We have the automated tools to make your project a success, with cutting-edge equipment, the highest industry standards and certifications, and a global supply chain platform that allows economies of scale while lowering supply chain risk in an increasingly volatile components market. We at Flashline EMS are your go-to EMS partner for anything from printed circuit board designs to assembly to mass production solutions.