Engineering Design

At flashlines EMS, We collaborate

with our clients to develope unique solutions.

And the use of collaborative product design guarantees that industry best practices are followed. Our engineering design services produce high-quality products and solutions that foster long-term, mutually benefit.

Product development services can be customized to meet your specific requirements.

Some customers come to us with only a sketch of an idea, and in these circumstances, we take on the entire project from conception to completion. Other customers have their design team and want to keep control of the fundamental elements of the design while enlisting our assistance with certain aspects of the design, such as mechanical or firmware development. Our approach begins with understanding your needs, establishing the solution design, project planning, prototype evaluation, system integration, and product quality validation, regardless of the breadth of services you require.

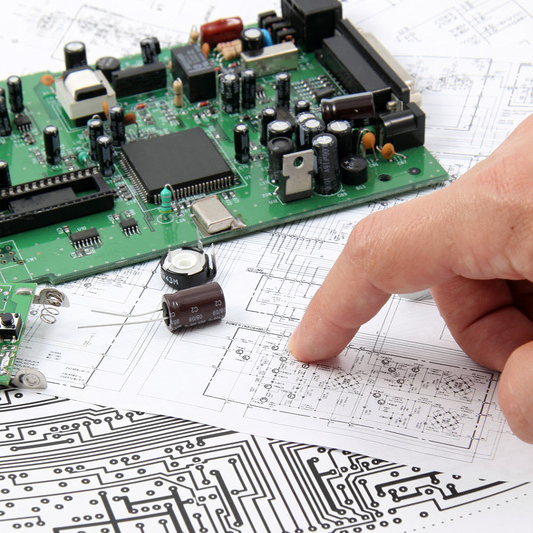

Embedded hardware development is an important element of product development.

Our hardware engineering services include board design, PCB layout, programmable logic, and enclosure designs that integrate FPGAs, DSPs, microprocessors, and complicated RF, analog, and power systems, from the basic architecture phase to production support. We thoroughly examine all PCB designs for timing, signal integrity, power, heat dissipation, and EMC/EMI compliance.

The design group at Flashline EMS combines knowledge with industry-standard design principles, ensuring that PCB layouts are tested and compliant with specific requirements.

Our hardware engineering services include board design, PCB layout, programmable logic, and enclosure designs that integrate FPGAs, DSPs, microprocessors, and complicated RF, analog, and power systems, from the basic architecture phase to production support. We thoroughly examine all PCB designs for timing, signal integrity, power, heat dissipation, and EMC/EMI compliance.

Mechanical design experts at Flashline EMS have a wealth of experience and understanding of designing fixtures and enclosures.

Because of our integrated nature, clients can rest assured that our mechanical engineers will design any assembly aid, test jig, or product enclosure using sound design for manufacturing principles. Flashline EMS will combine our electronics and mechanical design skills to ensure the most appropriate and effective interface with our customers’ products. We can provide simple and complex solutions for multi-board electronics enclosures, electrical cabinets, pogo pin interface jigs, and manufacturing test fixtures.

GET IN TOUCH

Flashline EMS is aninnovativeAI driven electronics manufacturing service (EMS) partner to leading OEMs, offering high-quality design, prototype, and full-scale production for anysorts of complex printed circuit boards assemblies. Flashline EMS has years of experience in the industry, resulting in vast expertise in printed circuit board manufacturing, assembly and Box build.

Flashline EMS is over 100,000 square feet state of art, brand new manufacturing facility with capacity to grow over 10 SMT lines aimed to serve prototype to high-mix volume for the customers globally.